Simple operation, superior wheel protection

Hunter Center-Clamp Tire Changers

Center-Clamp Tire Changers

Simple operation, superior wheel protection

Hunter offers four models of center-clamp tire changers for any need. From the popular three button leverless Auto34 to more basic models, damage free operation is attainable for all budgets.

Features at-a-glance

- Leverless and traditional options

- Center-shaft clamping

- Cam plate tightens under torque

- Adjustable height mounting

Specifications at-a-glance

-

860 ft-lbs.Torque

-

0-14+ rpmVariable Speed

-

26 & 34 in.Max Rim Diameters

-

19 in.Max Rim Width

Product family at-a-glance

Auto34R

Three button operation- 10-34 in. Capability

- Leverless polymer head

- Telescoping chassis sets diameter

- High-volume blast tank

- Dual roller arms

- Automatic indention

- Standard press arm

- Standard wheel lift

TC39 & TC37

Compact & capable- 10-26 in. Capability

- Leverless polymer head (TC39)

- Standard polymer head (TC37)

- Dual roller arms

- Manual indention

- Standard press arm

- Optional wheel lift and side shovel

TC33

Conventional Center-Clamping- 10-26 in. Capability

- Floating 3-point arm

- Standard polymer head

- PowerOut™ bead loosener

- Built-in blast inflation

- Optional plus device

- Optional press arm

- Optional wheel lift

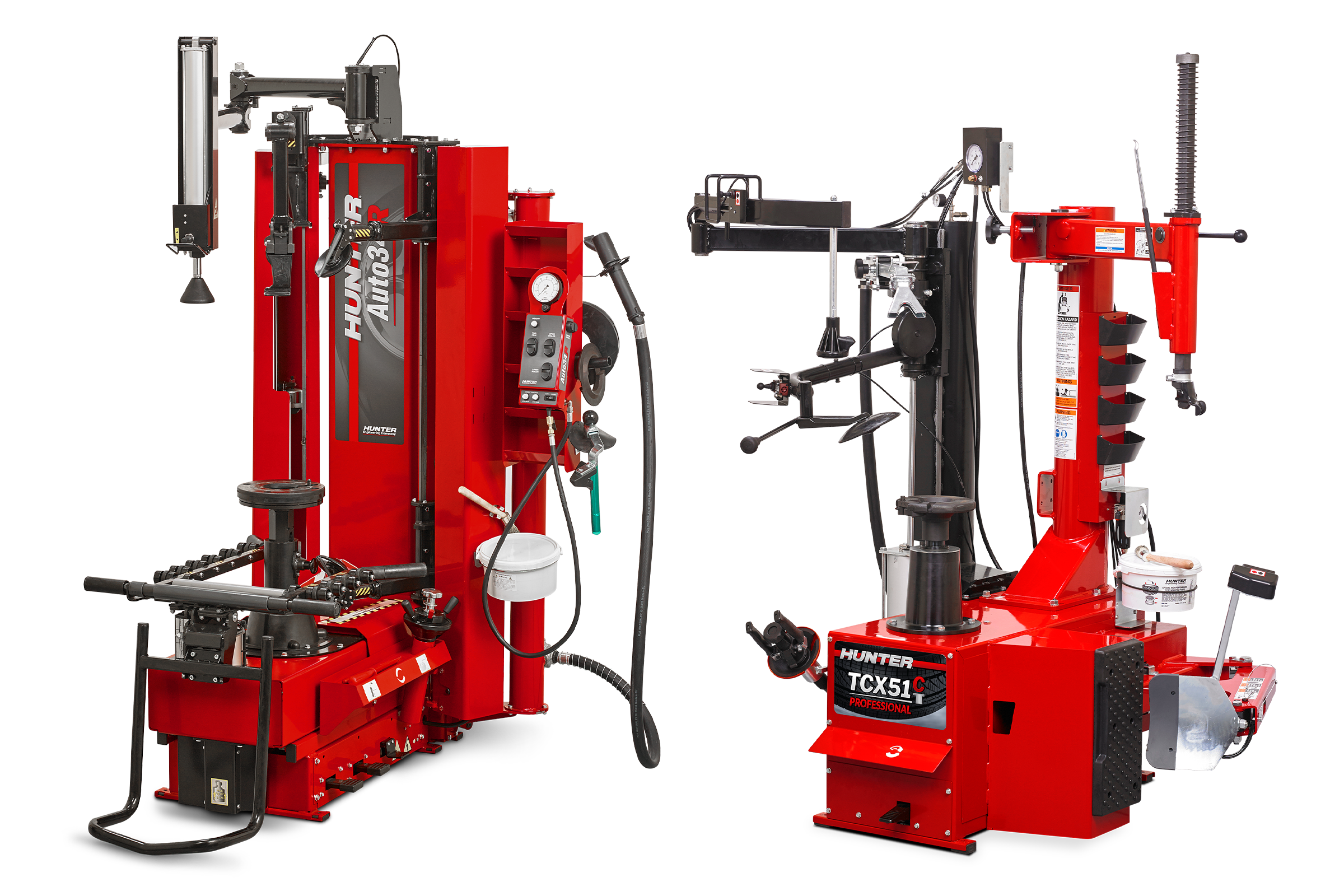

TCX51C

Powerful hybrid design- 10-30 in. Capability

- Manual swing arm

- Standard polymer head

- Bead press system with locking lower demounting disk

- FastBlast™ inflation system

- Heavyweight, rigid chassis

- PowerOut™ bead breaker shovel

- 220V 2-Speed Power

- Optional wheel lift

See them in action

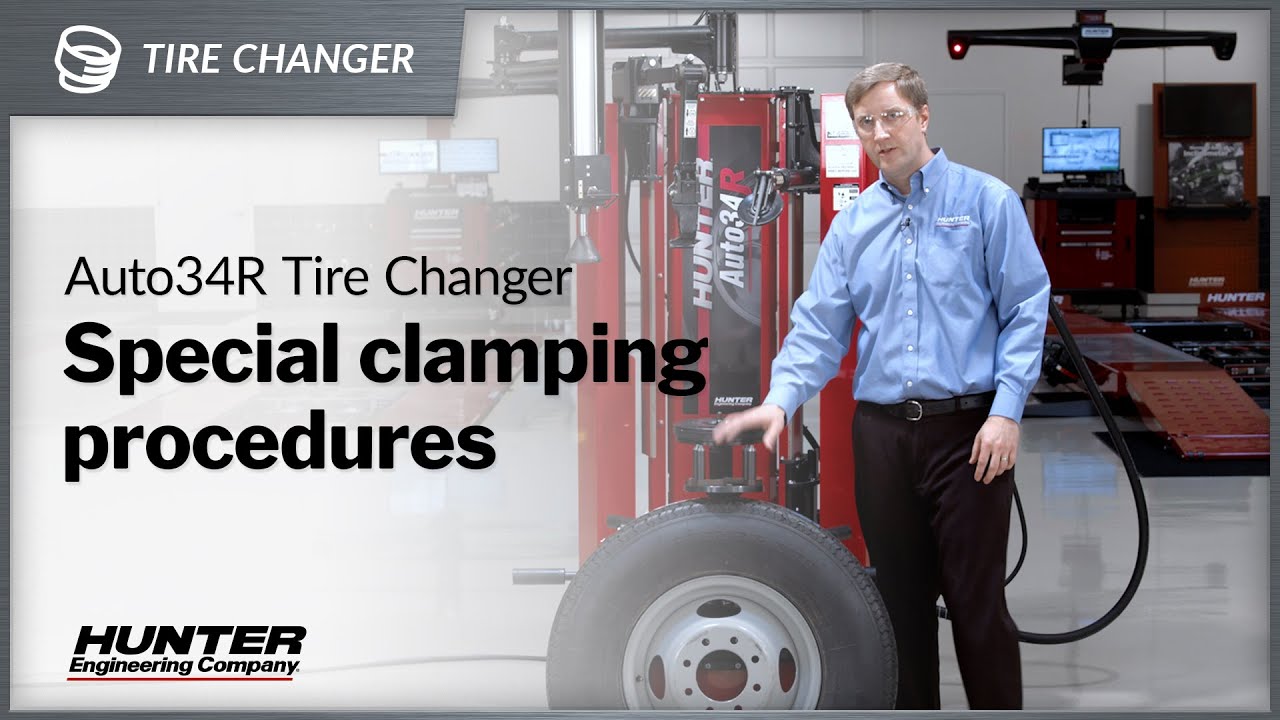

Auto34R Tire Changer

Hunter Engineering’s Auto34R Tire Changer is designed to quickly and easily service the broadest range of assemblies, from 10 to 34 inches, while also dramatically reducing the opportunity for tire and wheel damage.

The Hunter Auto34R Tire Changer: Detailed operations video

See tips and tricks for getting the most efficient performance from your Auto34R, including guidance for dealing with common difficult wheels.

Auto34R: Special clamping procedures

In this Auto34R instructional video, Tire Changer Product Manager Jim Hudson demonstrates a number of quick and easy clamping procedures for the types of wheels you may not see every day.

TC39 Tire Changer

Easy-to-use center-clamp tire changers with premium leverless demounting. The intuitive center-clamp system uses a simple clamping technique with three height positions.

TC39 Tire Changer Operation - Hunter Engineering Company

A quick operation video explaining the easy-to-use lever-less center clamp tire changer, with bead press arm to assist in mounting difficult tire and wheel assemblies.

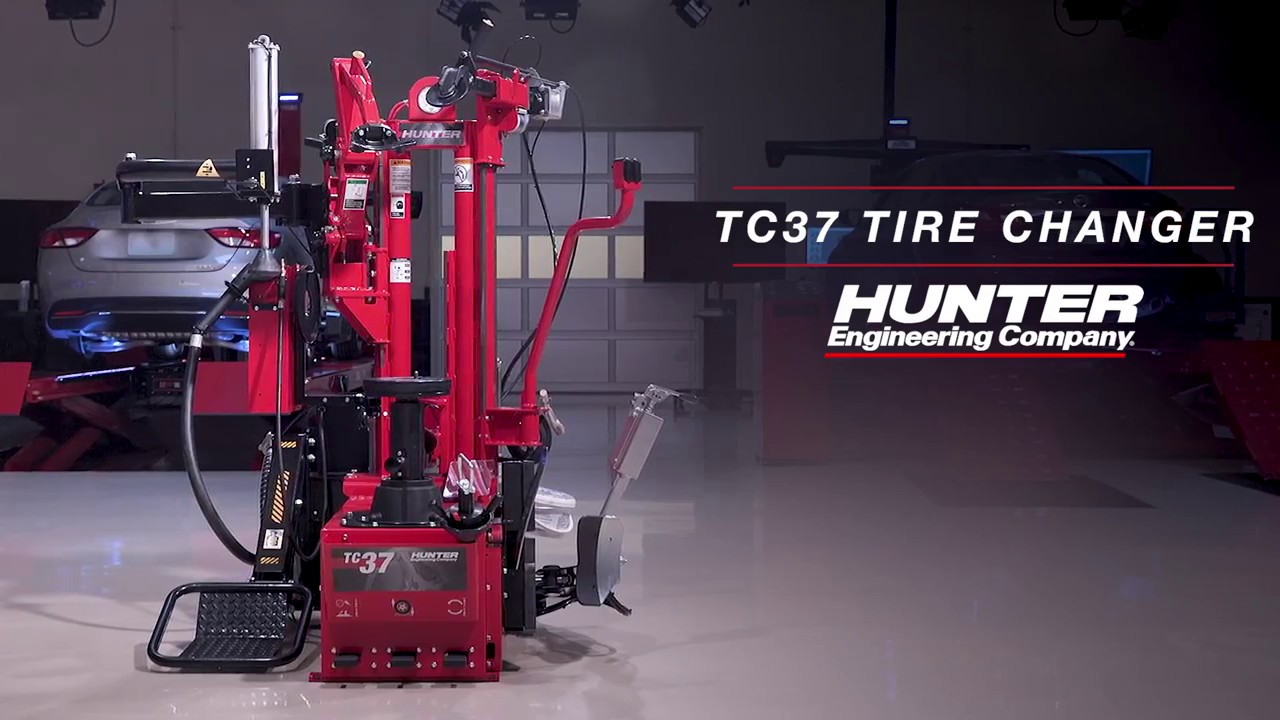

TC37 Tire Changer

Easy-to-use conventional center-clamp tire changer with bead press arm to assist in mounting of difficult assemblies. Optional wheel lift eases servicing of large assemblies.

TC37 Tire Changer Operation - Hunter Engineering Company

Watch a demonstration on the easy-to-use conventional center clamp tire changers with bead press arm to assist in mounting of difficult assemblies.

The Hunter TC33M Tire Changer: Standard operation

See a demonstration of quick and efficient demounting and mounting, helpful tips on counterclockwise rotation on bead-breaking, mounting with the bead over and under the mount head, and keeping the top bead in the drop center.

Did you know?

73% of assemblies today are considered difficult-to-service

Low-profile, run-flat, large diameter and heavy assemblies require skilled technicians when using conventional tire changers.

Being equipped with the most advanced, technology on the market today allows the equipment, instead of the technician, to eliminate fitment challenges.

Give your technicians a break

Consistent service times, fewer technician decisions and autonomous WalkAway™ mode makes tire service on the Hunter Revolution™ simpler than ever.

Auto34R Exclusive Features

Precise Diameter Control

Electric telescoping chassis is smooth and responsive.

Simple controls

Auto34R features three button operation

Automatic Indention

Simplifies and speeds bead loosening

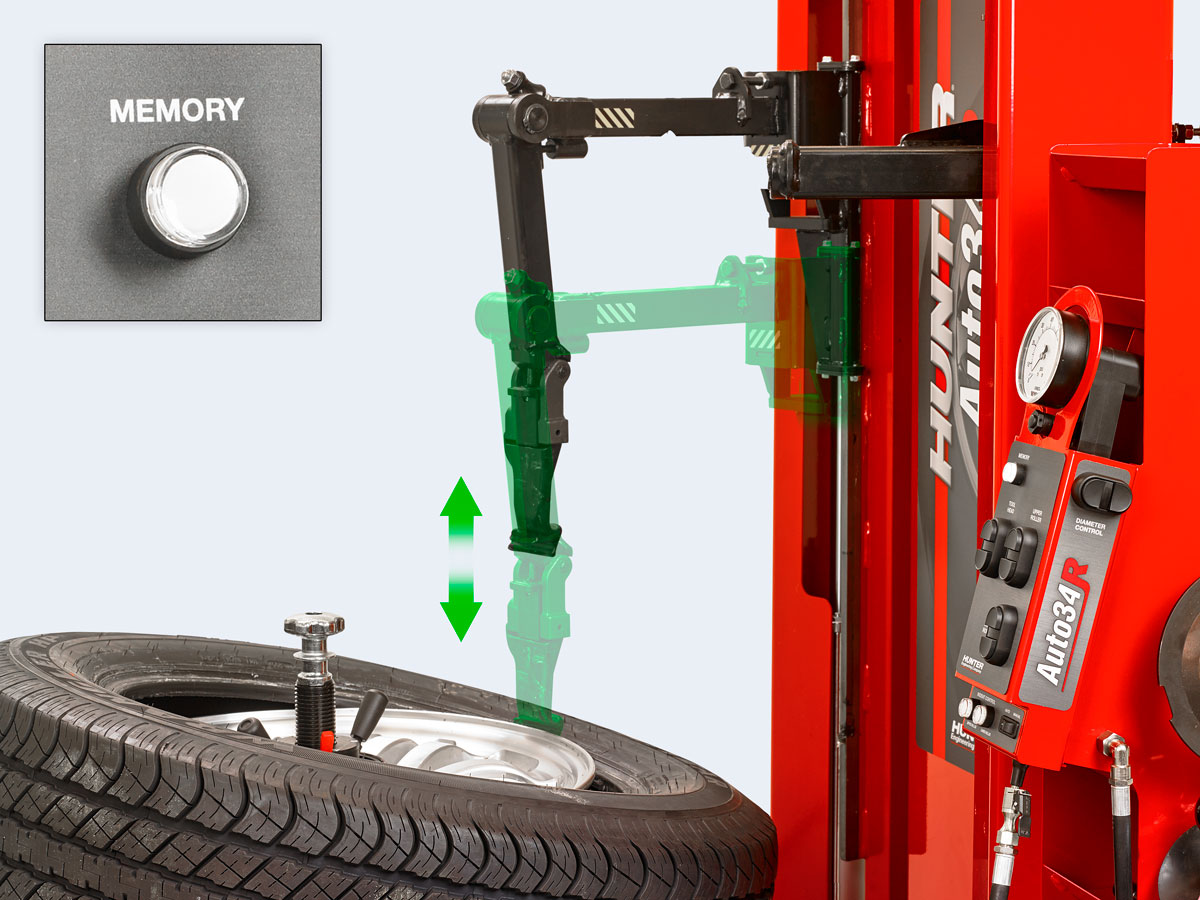

Memory Function

Quickly returns toolhead to preset location

High-volume blast tank

Slim profile and large capacity to seat truck and SUV tires

Small footprint

Improved features save valuable floor space

Make wheel servicing safer and easier

Leverless polymer toolhead

Auto34R & TC39

- No scratch polymer head functions as its own lever

- Head is wide and thin for very low mounting stress

- Head does not ride on the wheel face for scratch free operation

Conventional mounthead

TC37 & TC33

- Durable polymer head for use with traditional levers.

- Prevents wheel damage and follows the rim edge, no diameter adjusting needed.

- Locks in vertically for clad wheel protection (TC37 only)

Powerful press arm

Auto34R, TC39 & TC37, optional on TC33

- Assists mounting toughest tires

- Demounting assistance for runflats

Dual bead rollers

Auto34R, TC39, TC37

- Easy bead loosening

- Lower roller demount bottom bead, making heavy tires managable

- Dual rollers essential for match mounting and bead massage

Plus device

TC33

- Assists with a broad range of tires from passenger cars to medium-duty trucks

- Aids in lubricating, lifting and guiding the tire into the drop-center

- Adjustable roller angle

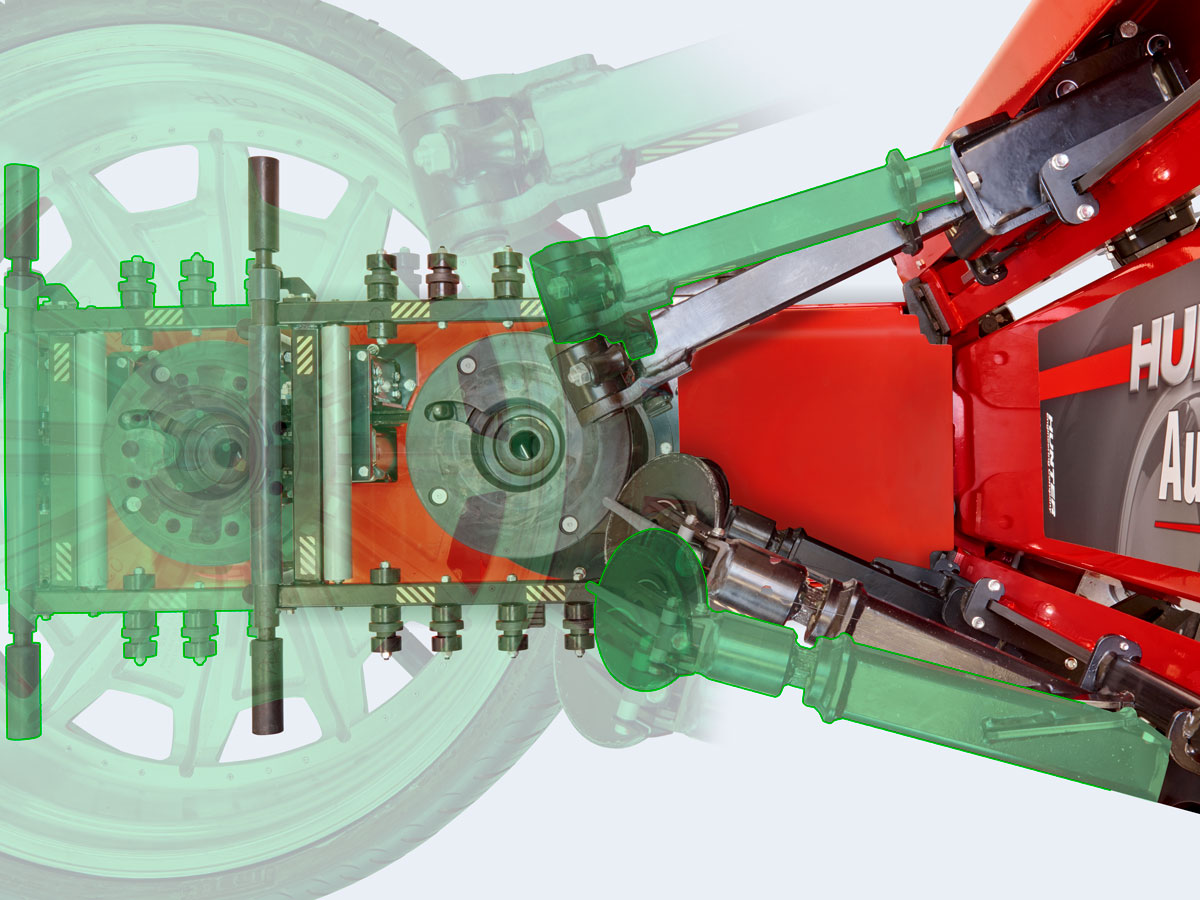

Secure wheels with no damage

Center-clamp

- Grip from the strongest part of the rim

- No teeth to damage rim

Cam plate

- Tightens just as much as needed to grip wheel

- Three adjustment heights adapt to all wheel types

Flange plates (optional)

- Two options for clad wheels and reverse wheels needing extra protection

Order Hunter tire changer accessories online

Order standard tire changer consumables 24/7 for the industry's leading tire changing machines at Shop Hunter!

Protect your customers' wheels today!

Ease-of-use features for technicians

Wheel lift (Auto34R)

Standard on Auto34R

Pick and place lift makes lifting and clamping heavy assemblies easy

Wheel lift (TC models)

Optional on TC39, TC37 & TC33

Simplifies lifting heavy assemblies. Safe and away from work area.

PowerOut side shovel

Optional on TC37 & TC39, standard on TC33

Break beads effortlessly to make tire service easier.

Blast inflation

Handheld air blast nozzle directs burst where needed to seal beads.

Additional features

Variable speed

- 0-14+ rpm forward speed is infinitely variable

- Slow speed for reverse

Powerful drive

860+ ft-lbs of torque won't stall on tough assemblies

Did you know?

Bead massage reduces wheel vibrations

Bead massage reduces road force vibration by an average of seven pounds. Some assemblies can see road force reductions well over 20 pounds!

To bead massage you need a dual bead roller center-clamp tire changer. While still clamped, inflate the tire to OEM recommended pressure and refit the core. One at a time, bring the bead roller against the sidewall of the tire at the rim edge and press approximately 1/4 inch into the tire. Rotate two or three revolutions for each bead.

Bead massage takes less than a minute, but can significantly reduce road force, a leading cause of vibration.

Send a message to your local Hunter business consultant to receive a free pricing quote or product demo.

This contact form is intended for legitimate Hunter equipment and service inquiries. All other use is prohibited and will be discarded. See Full Terms of Use

Specifications

|

|

|||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Your local Hunter service representative can answer questions, help with equipment operation and provide on-site training.

Purchase genuine Hunter replacement parts online

This contact form is intended for legitimate Hunter equipment and service inquiries. All other use is prohibited and will be discarded. See Full Terms of Use

Having trouble deciding?

Here are some tips

See how other shops are using them

Equip your shop with match-mounting capabilties.

Eliminate wheel vibrations by pairing the tire machine with a Road Force® Elite wheel balancer.

Documents

Accessories

Hunter's 3-Year Warranty

We stand beside our equipment and your purchase.

Hunter Engineering Company warrants new equipment replacement parts for three years and labor for six months.

Explore further

Revolution™

WalkAway™ from your tire changerWalkAway™ from your tire changer to perform other tasks while it automatically demounts the tire.

Hunter service

Largest in the industryHunter deploys the largest service force of highly-qualified representatives in the industry.

Innovation Team

Award-WinningHundreds of patented and exclusive features begin with the research and development team of mechanical, electrical and software engineers.