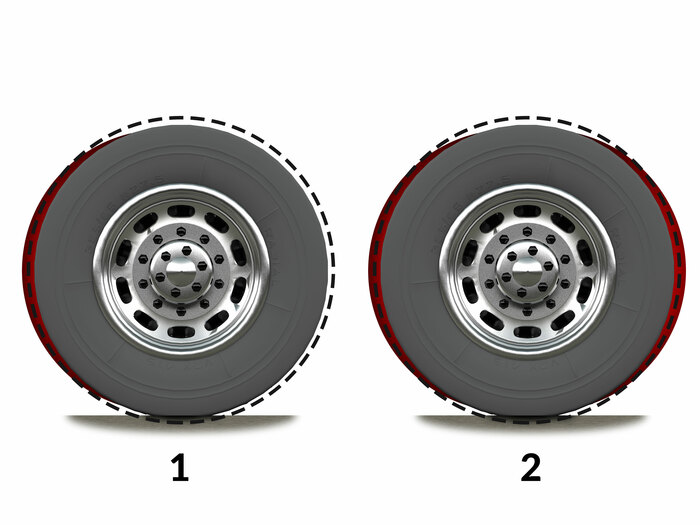

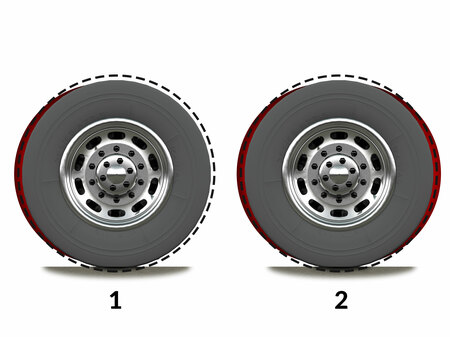

Dual tire assemblies with aligned high spots (1) behave like single assemblies with runout. Marking and installing wheels with high spots 180 degrees opposed (2) makes the dual assembly more round than the two assemblies alone and reduces vibration.

WHEEL BALANCER

HD ELITE™ WHEEL BALANCER

The best features of Hunter's Road Force® Elite makes servicing heavy-duty bus and truck wheels even easier than before, using patented vision system and diagnostic capabilities designed to solve vibration issues.

HD Elite™

/

HD Elite™ at-a-glance

Measure runout and balance faster than any traditional balancer

Eliminate error opportunities with the patented laser vision system

Solve vibration problems by detecting and matching the high spot of the tire using the diagnostic load roller

Ensure proper centering with patented automatic CenteringCheck®

Maximize efficiency using SmartWeight® technology

True self-calibration with patented eCal auto-calibration

Service car and light-truck assemblies and provides proper mounting up to 226.80-kg.

THE WORLD'S #1 HEAVY-DUTY DIAGNOSTIC BALANCER

The HD Elite™ combines advanced diagnostics features to detect vibration causing issues in heavy-duty assemblies.

Unmatched Speed

Measure runout and balance faster than any traditional balancer

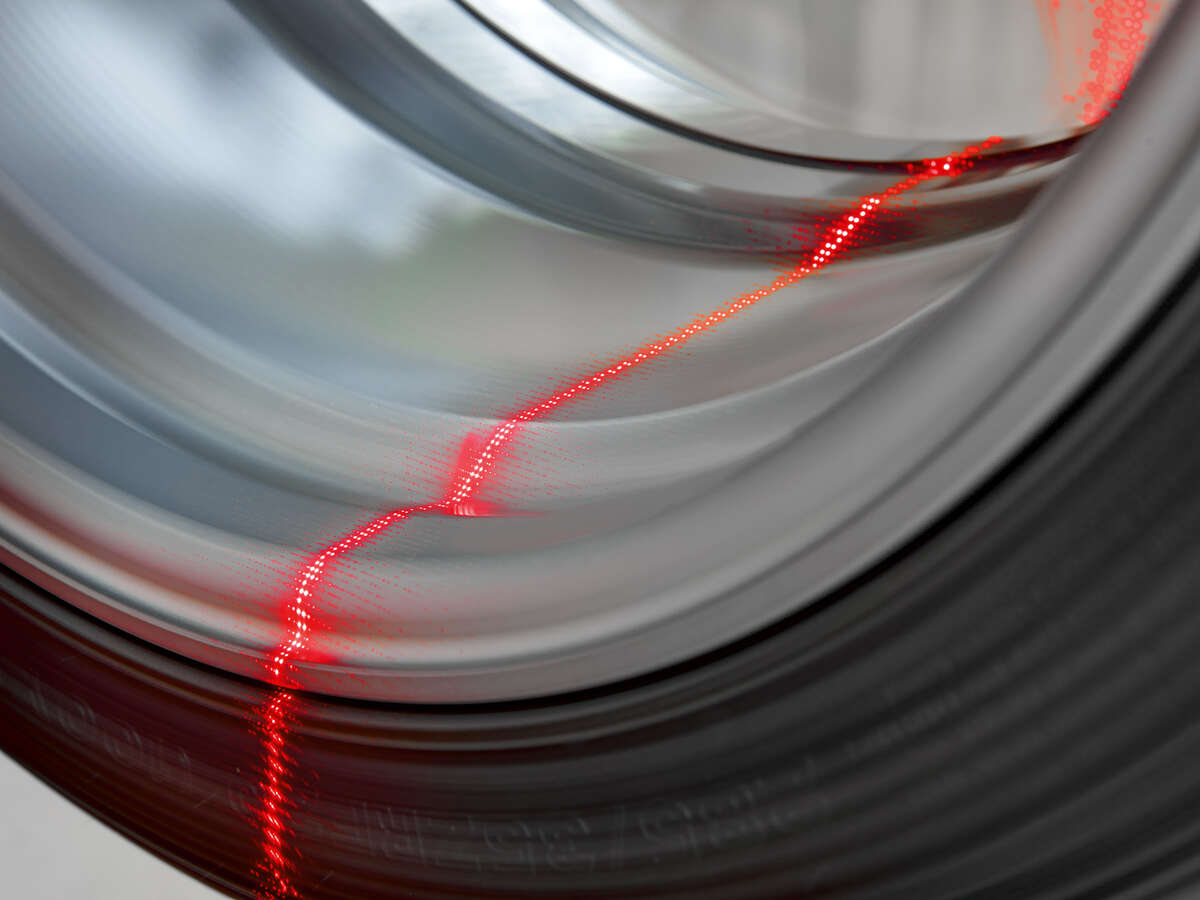

Laser Vision System

Eliminate error opportunities with patented laser vision system

Diagnostic Load Roller

Roller detects high spot of tire and allows machining

Aid proper mounting

The built-in wheel lift can handle assemblies up to 500 lbs

Maintaining trust with HD and commercial customers

Thomas Tire relies on Hunter equipment to maintain that trust. “Our dad was always a firm believer in investing in quality, and that’s what we’ve done.”

Hunter's HD Elite™

A heavy-duty wheel balancer that combines cutting-edge features of Hunter’s Road Force® Elite and ForceMatch® HD balancers to help eliminate wheel-related vibration and increase truck tire life.

Laser-Driven Wheel Balancing with the New HD Elite™

The HD Elite™ is elite for a reason: The automatic process provides the most valuable data with the least operator involvement of any wheel balancer on the market.

HD Elite™ Wheel Balancer: Basic Operation

Hunter’s HD Elite™ is a heavy-duty wheel balancer that combines the cutting-edge features of Hunter’s Road Force® Elite and ForceMatch® HD balancers to eliminate wheel-related vibration and increase truck tire life.

HD Elite™ Wheel Balancer: Basic Balancing

Hunter’s HD Elite™ is a heavy-duty wheel balancer that combines the cutting-edge features of Hunter’s Road Force® Elite and ForceMatch® HD balancers to eliminate wheel-related vibration and increase truck tire life.

HD Elite™ Wheel Balancer: Basic Force Matching

Hunter’s HD Elite™ is a heavy-duty wheel balancer that combines the cutting-edge features of Hunter’s Road Force® Elite and ForceMatch® HD balancers to eliminate wheel-related vibration and increase truck tire life.

CALCULATE YOUR PAYOFF AND PROFITS

Patented vision technology measures and generates an exact wheel model

Wheel Dimensions

Automatically determine weight plane locations

Weight Mode

Selects clip or tape weight usage

Rim Runout

Calculates ForceMatch® solution

Rim Profiled

Creates a three-dimensional model of the rim

SmartWeight® Optimized

Allows more single-weight solutions

Spoke Location

Prioritizes hiding tape weights behind spokes

MATCH DUAL ASSEMBLIES TO MAXIMIZE TIRE LIFE

- Opposing high spots

- Unequal load on duals

- Revolutions per mile

Opposing High Spots

Unequal Load on Duals

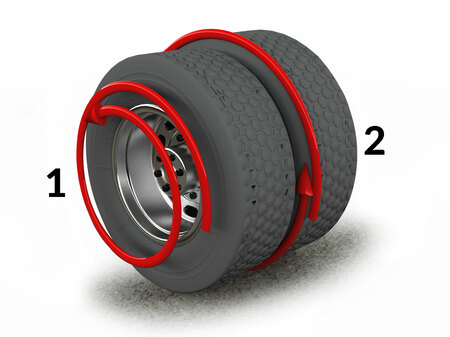

Mismatched diameters on dual tires causes the larger tire (2) to carry more load, thus generating more heat and reducing tire life. The lesser diameter tire (1) may develop premature tire wear due to slippage relative to the road surface.

Revolutions per mile

Dual tire assemblies with mismatched diameters cause the smaller tire (1) to turn faster and thus be dragged along with the larger tire (2). For example, if one tire has just 1/8-in. less tread depth than the other, it will be dragged 33.3 feet per mile traveled.

Eliminate wheel-related vibration for a smooth ride by matching the tire to the wheel assembly

Boost Returns with ForceMatch®

Make Forcematch® a profit center

Solving two new customers vibrations per month @ $120 per session, could generate: $2,106 Gross annual profit (30% labor & parts)

Forcematch every assembly and avoid comebacks

Comebacks could cost your business $1,800 in opportunity cost annually.

1 Comeback per Month x 1.5 Hours to diagnose and fix x $100 Shop Rate = $150 Opportunity cost monthly

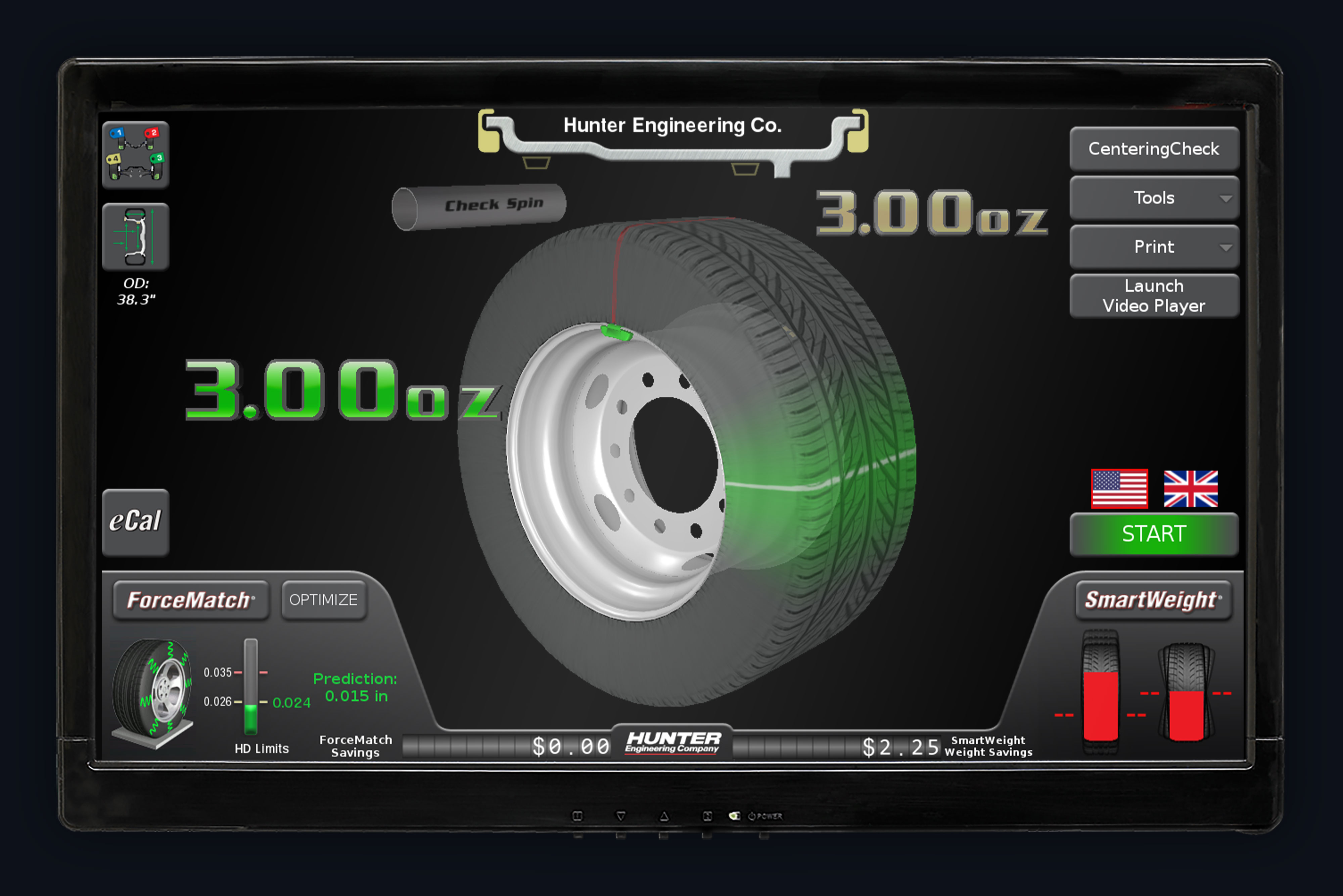

Powerful controls and real-time 3D graphics

See live balance results from 3D graphics with advanced features and controls available at your fingertips.

TruWeight™

TruWeight™ provides live navigation through selection and placement of wheel weights.

Rim Dimensions

One-touch button shows all rim dimensions.

Weight Mode

Rim cutaway graphics shows the weight mode.

Controls

Easy-to-access navigation to other functions and screens.

Language

Switch language on the fly.

ForceMatch®

See assembly runout value and limits

SmartWeight®

SmartWeight® panel provides clear indication of wheel balance conditions.

Savings

See your ForceMatch® and SmartWeight® savings add up.

Weight Value

Touching weight value servos wheel to weight location.

OD: 38.3

Accomdating 38.3 inch wheel assemblie diameter.

Load Roller

Roller detects high spots of tire and allows matching.

See all the features

Automatic CenteringCheck®

Miscentering during wheel balancing procedures is the number one cause of improper balancing and customer comebacks. Automatic CenteringCheck® always monitors wheel centering to reduce setup errors.

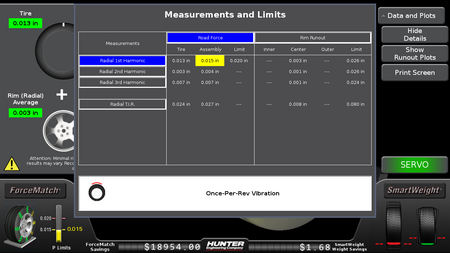

ForceMatch® Prediction

Simple graphics illustrate how to optimize assembly. Live, color-coded graphics show the technician force variations.

Assembly Diameter Display

Easily accessible to make matching dual assemblies a snap.

High-Spot Display

Mount dual assembly high spots 180 degrees apart to increase tire life.

On-Board Videos

View operations videos to help train technicians.

Save time & money with exclusive features

SINGLE-WEIGHT SOLUTIONS

SmartWeight® technology determines optimal weight placement to avoid excessive use and save money.

VIEW YOUR SAVINGS

Track your weight usage savings on-screen.

ANY WHEEL SIZE

Never turn down a customer. Service car and light truck wheel assemblies as well.

TOUCHSCREEN INTERFACE

Intuitive, easy-to-learn controls.

WHEEL LIFT

Easily lift wheel assemblies up to 226.8 kg. and ensure a proper mount.

HAMMERHEAD® SYSTEM

Optional

Top-dead-center laser system assists in easy weight placement.

ACCESSORIES STAND

Standard

Adaptor tree conveniently stores oversized balancer accessories.

See how you can provide a smooth, over-the-road ride for your customers.

Need help ordering parts?

We are ready to help!

Receive Same-Day or Next-Day Shipping

Receive Same-Day or Next-Day Shipping

![]() Parts Built for Quality and Performance

Parts Built for Quality and Performance

![]() Seamless and Reliable Installation

Seamless and Reliable Installation

![]() Unmatched Support, Every Step of the Way

Unmatched Support, Every Step of the Way

HunterNet® Portal

Connect your equipment to your business to maximize your shop's performance, simplify customer discussions with selling tools, and view extensive undercar information.

Easy Consumable Ordering

Replenish genuine Hunter consumable parts at your convenience.

Monitor Your ROI

See your equipment payback in real time.

View Your Performance

Set goals and see how your business performs day-to-day.

Recall Tyre Change Results

Every tyre change result is logged with service time, wheel dimensions, images, and tyre pressure.

Receive Daily Reports

Setup to receive daily Push Reports to keep your goals and performance in check.

Track Revenue

Track your profits and potential amount if all needed services were sold.

Specifications

|

|

|||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

The HD Elite™ Wheel Balancer is a Class 2 laser product.

The HammerHead® TDC is a Class 1 laser product.

LASER RADIATION - DO NOT STARE INTO THE BEAM OR VIEW DIRECTLY WITH OPTICAL INSTRUMENTS. Viewing the laser output with magnifiers or related optical instruments within a distance of 100 mm from the laser aperture may pose an eye hazard.

Gallery

Because of continuing technological advances, features and configurations shown in customer photos may vary.

FAQ

Documents

-

Brochures

-

Specification Sheets

-

Accessories

Receive same- or next-day service

Get a free quote or on-site demo

Register for ASE-accredited training

General information & questions

This contact form is intended for legitimate Hunter equipment and service inquiries. All other use is prohibited and will be discarded. See Full Terms of Use

Hunter Engineering Company warrants new equipment replacement parts for three years and labor for six months.

From raw steel to finished product. When you choose Hunter, you're investing in more than 1,000 American workers.